Τεχνολογία. Καινοτομία. Ανάπτυξη.

Η Εταιρεία

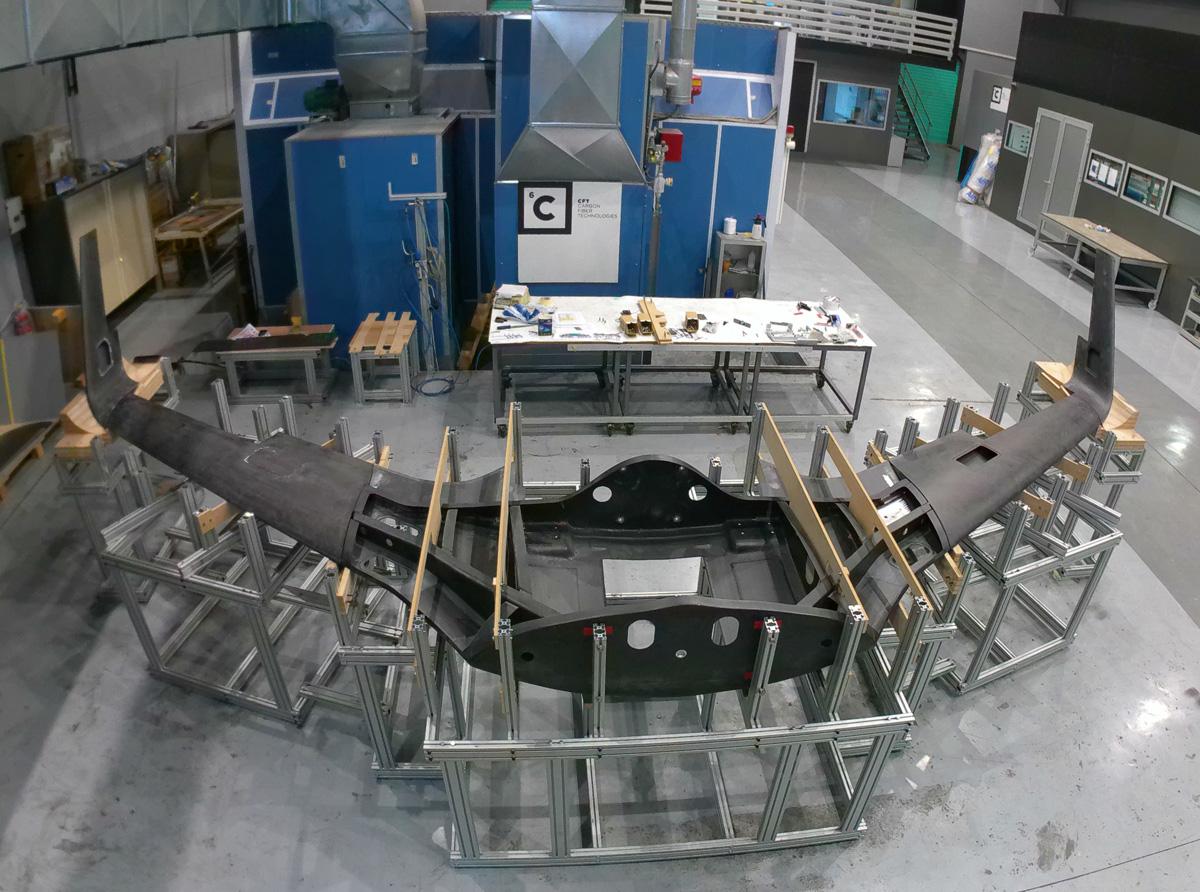

Ποιοι είμαστεΗ CFT ιδρύθηκε τον Δεκέμβριο του 2013 και εδρεύει εντός της ΒΙ.ΠΕ Σταυροχωρίου Κιλκίς με τίτλο «CFT CARBON FIBER TECHNOLOGIES PRIVATE COMPANY».

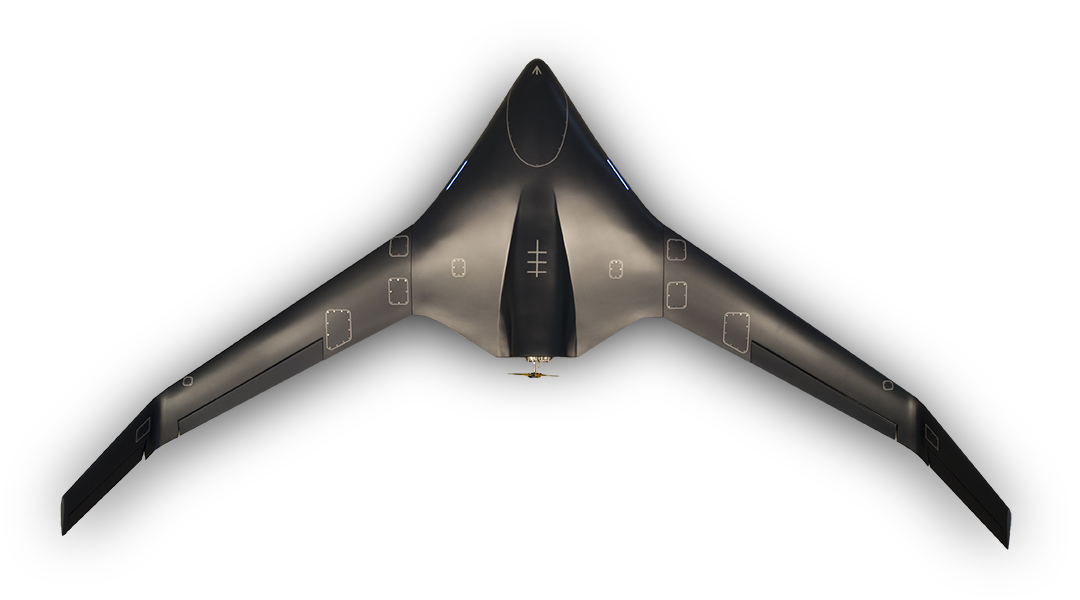

Οι τομείς ενασχόλησης της CFT είναι η κατασκευή αντικειμένων από σύνθετα υλικά (composites) καθώς και η κατασκευή αντικειμένων με τη χρήση προγραμματιζόμενων εργαλειομηχανών CNC.

Αποτελούμε ένα δυναμικό κέντρο τεχνογνωσίας και εμπειρίας που έχει ως στόχο την ολοκληρωμένη υποστήριξη όσων αναζητούν λύσεις υψηλής καινοτομίας, δίνοντας ζωή σε μελέτες οποιασδήποτε μορφής και οποιουδήποτε μεγέθους.

Αξιοποιώντας τη συσσωρευμένη τεχνογνωσία που διαθέτουμε χάρη στο ευρύ τεχνολογικό μας υπόβαθρο, μέσα από τη δραστηριοποίηση μας σε διάφορους βιομηχανικούς κλάδους, επικεντρωνόμαστε στην εύρεση προηγμένων λύσεων, έτοιμες για βιομηχανική παραγωγή, καλύπτοντας στο έπακρο τις ανάγκες των πελατών μας.

Η CFT διαθέτει πιστοποιητικό διασφάλισης ποιότητας ISO 9001:2015.

Τομείς

01

ΤΜΗΜΑ ΣΥΝΘΕΤΩΝ ΥΛΙΚΩΝ

Κατηγορίες έργων